We use cookies to provide great user experience. By continuing on this site you accept use of the cookies.

We use cookies to provide great user experience. By continuing on this site you accept use of the cookies.

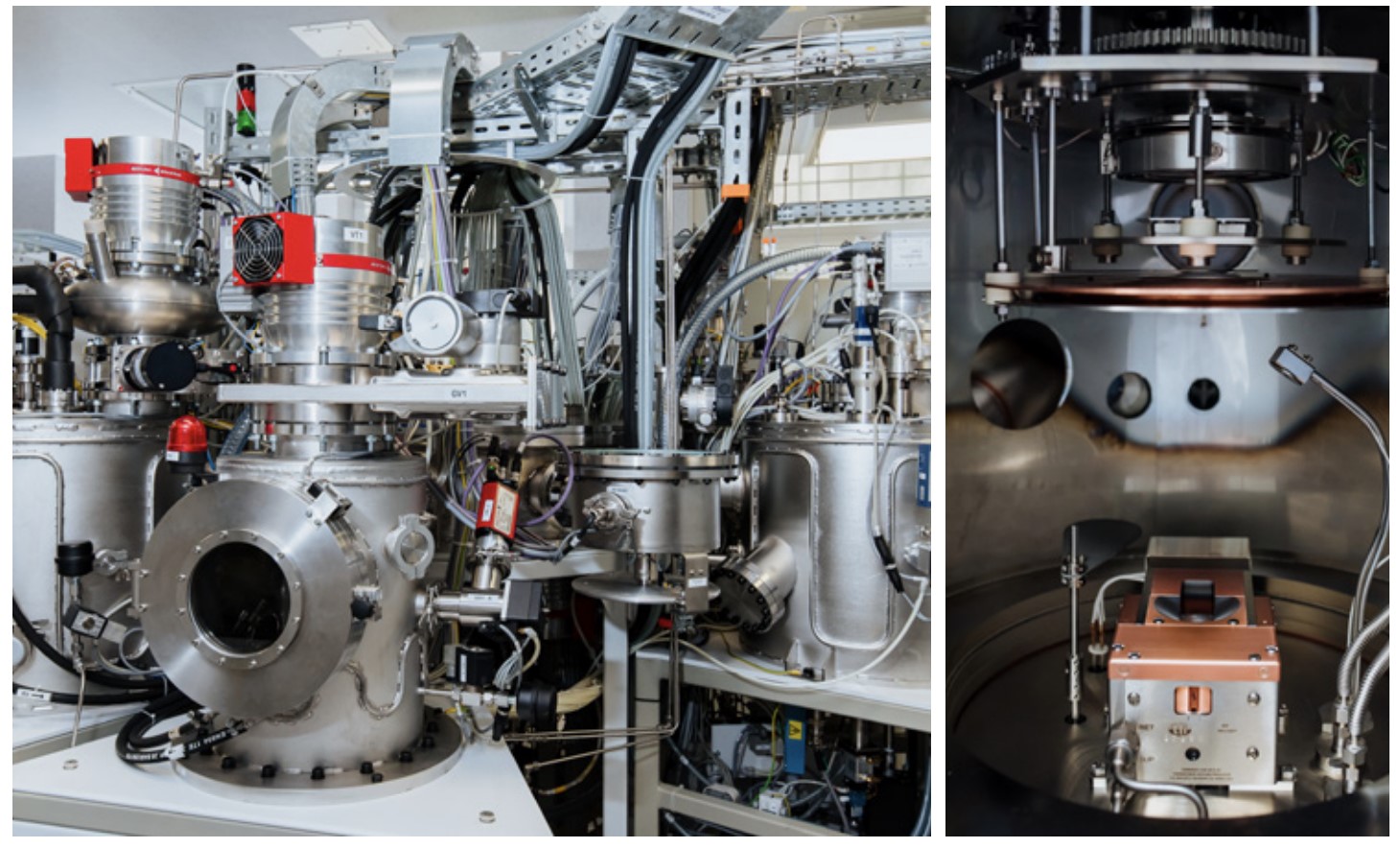

Multi-functional cluster tool and expertise in vacuum deposition of thin films for inorganic and organic materials

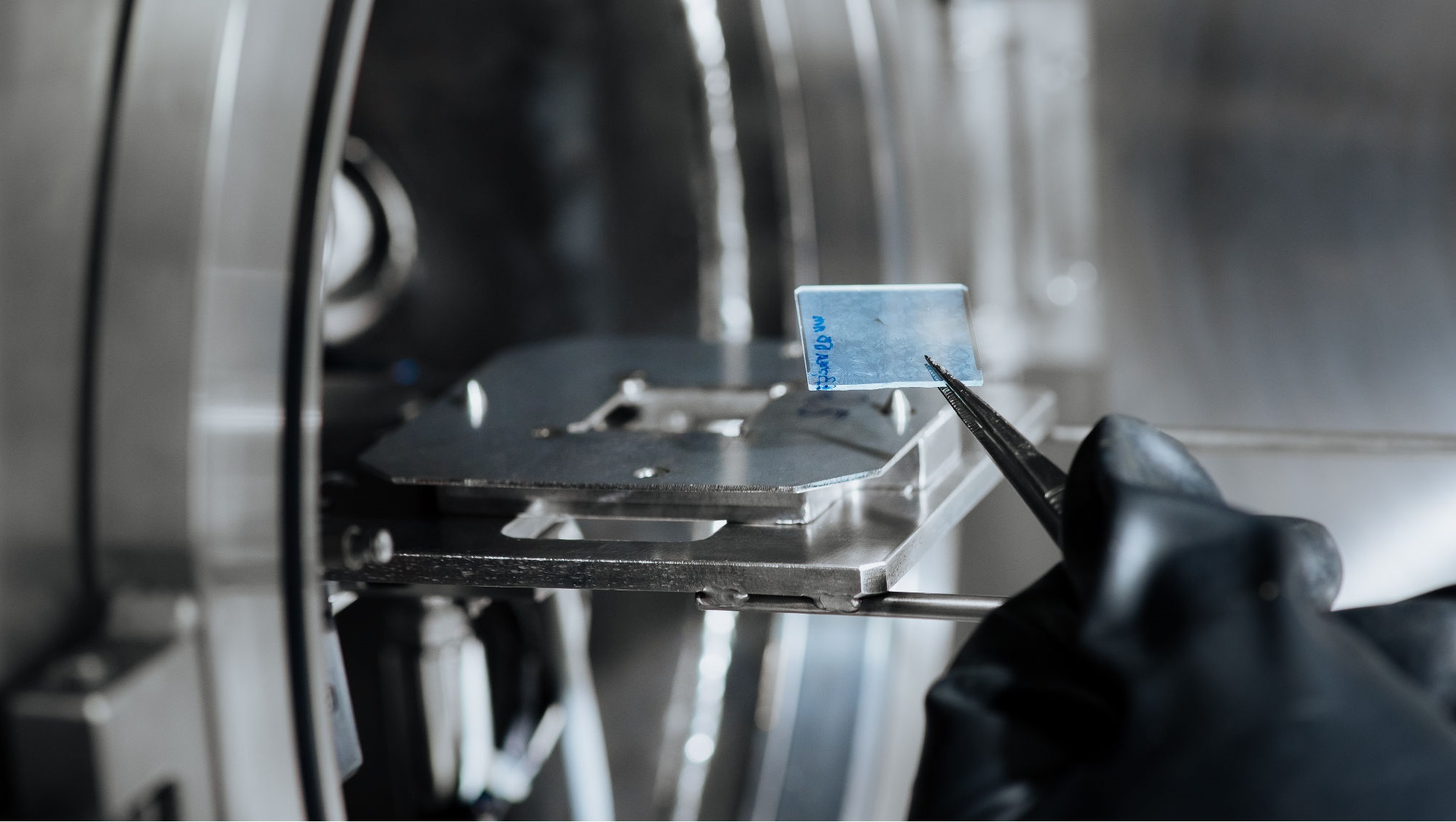

Our custom-made cluster tool can be used for research and development projects, feasibility studies and general academic work in the field of thin-film technologies. Sample manufacturing aimed at product prototyping form market evaluation of out-of-box technologies.

Each chamber can operate independently due to individual pumping, control and utility flanges. All chambers can operate simultaneously. Several different deposition processes are available.

For metal, alloy, oxide, transparent conductive oxides, electrochromic, thermochromic, nitride, carbide, polymer, semi-conductor and P-I-N thin films.

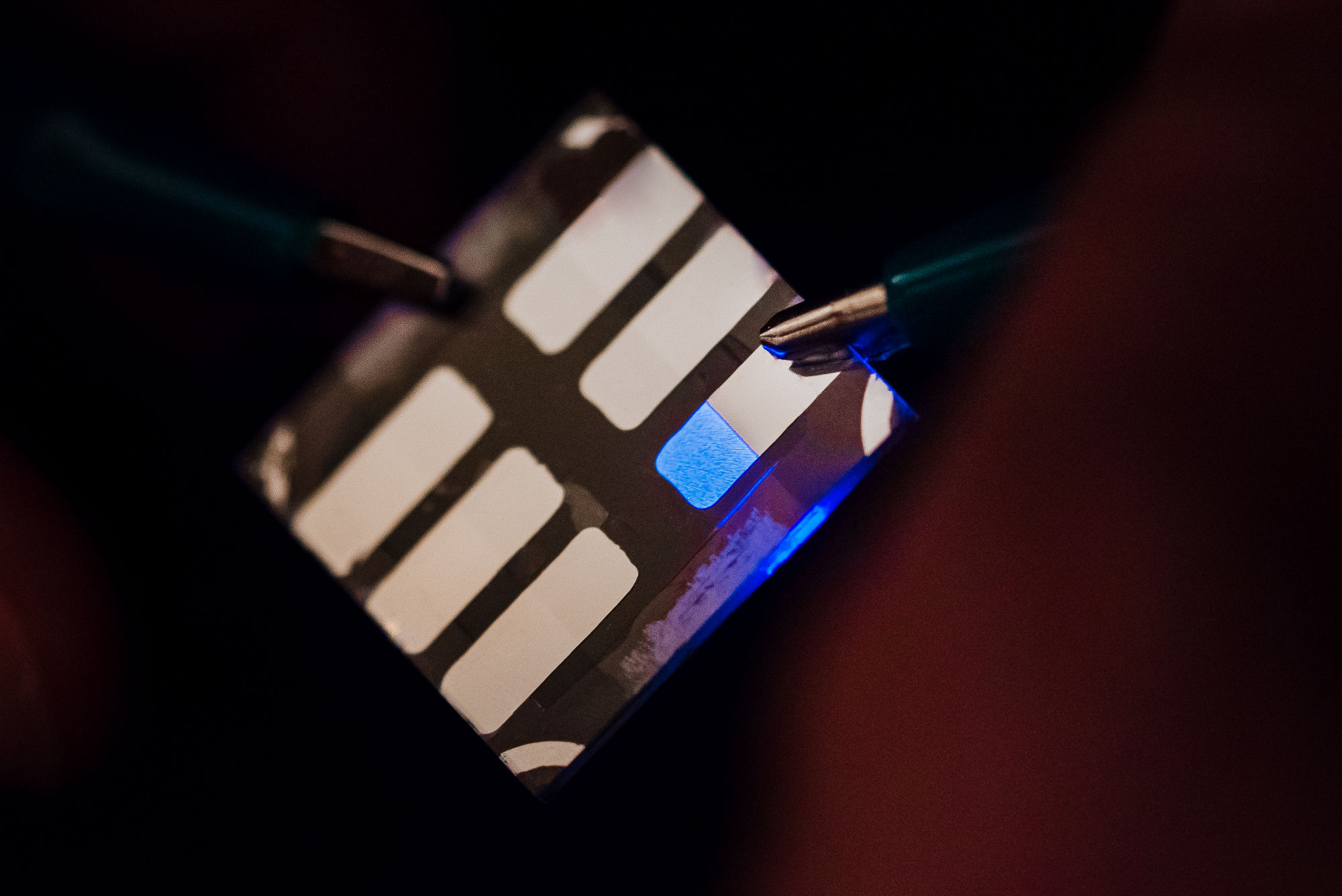

For organic thin films and prototyping of OLEDs, organic photovoltaics and organic electronics.

For metals and inorganic materials.

For fast deposition and high thickness films.

ISSP can fabricate experimental devices (e.g. organic light emitting diode). We work with original materials as well as commercially available materials.